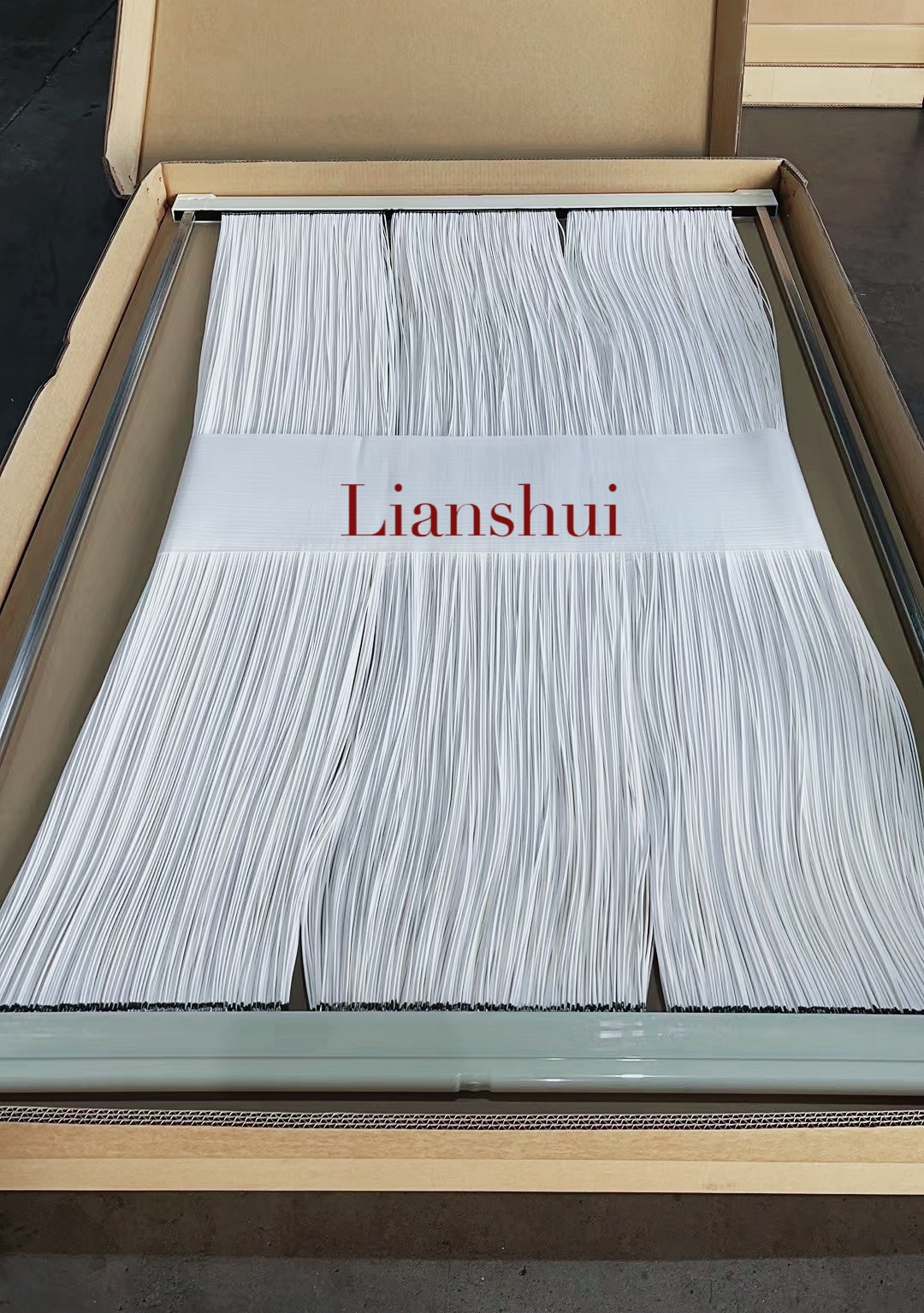

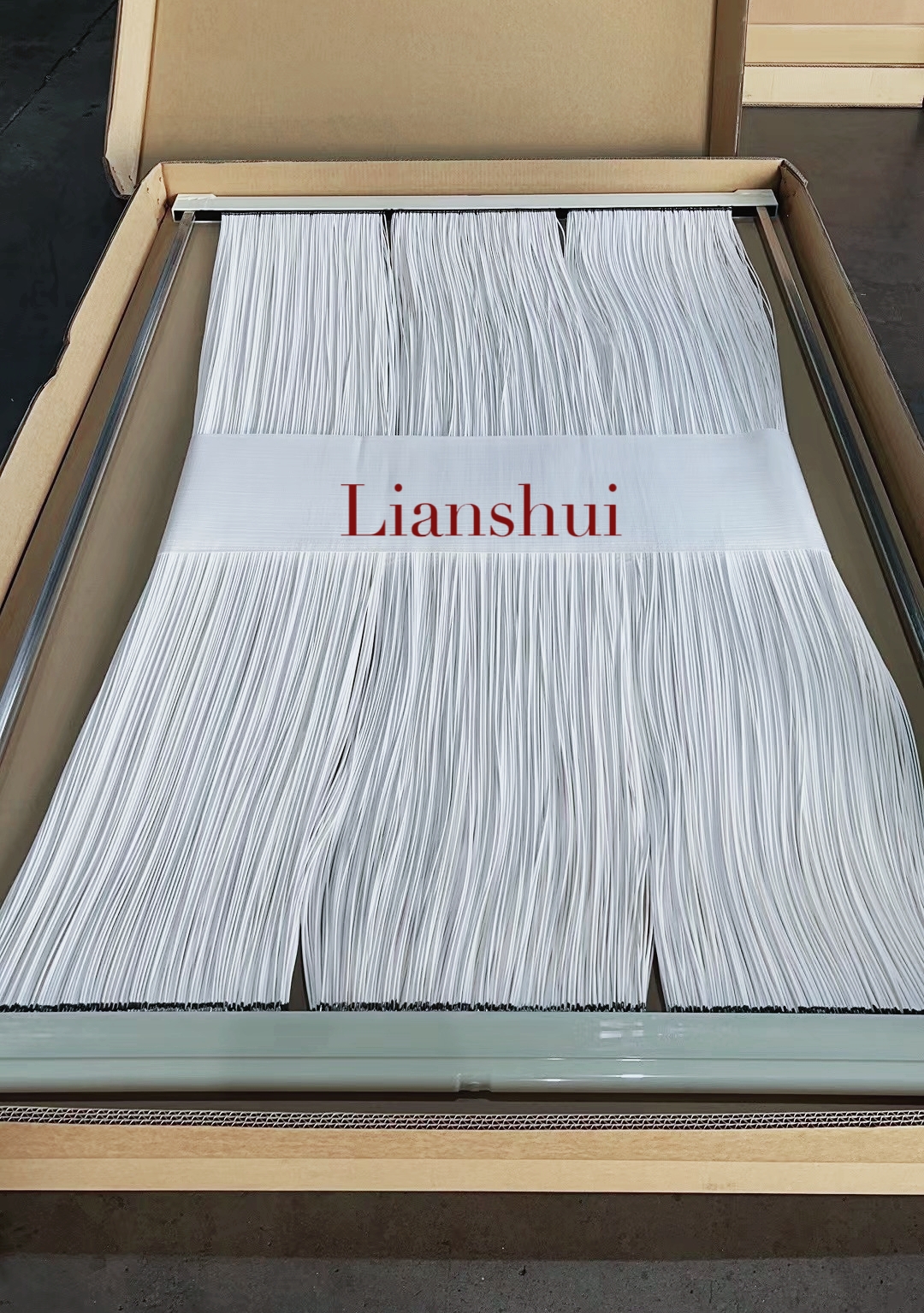

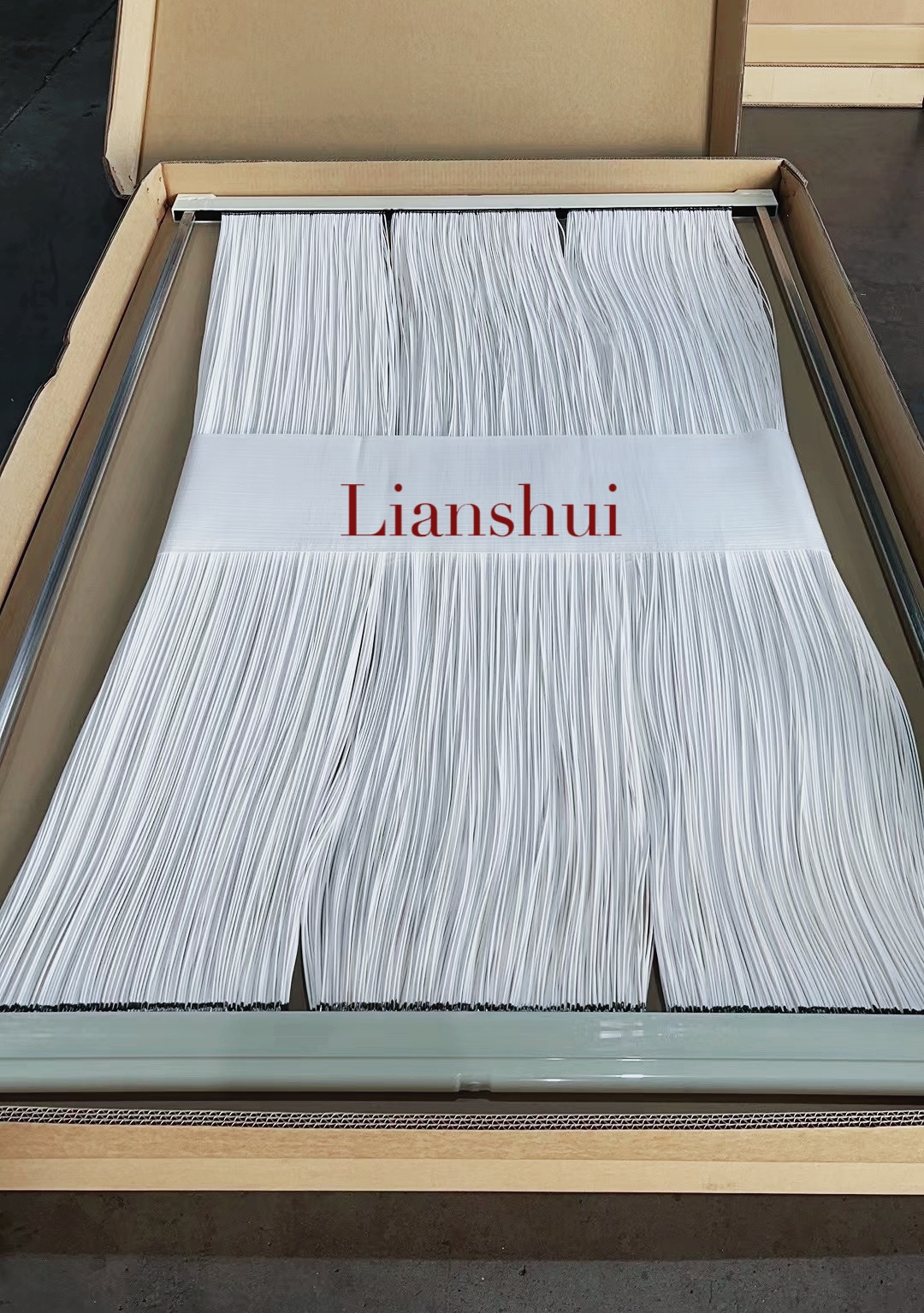

日本三菱抛光树脂

文章出处: 人气:发表时间:2020-05-14

日本三菱的抛光树脂到底有哪些?实际上日本三菱对于抛光系列树脂分的层次比较精细,有:DIAION KAM115U / DIAION MUPB PLUS / DIAION MUPBT / DIAION SMT50 / DIAION SMT100L / DIAION SMT110L / DIAION SMT110X / DIAION USMT100 / DIAON SMT200L 等.....

今天小编带大家了解一下我们常说的精混床抛光树脂及装填时的注意事项。一般抛光混床用于超纯水处理系统末端,又称之为一次性混床,用来保证或更好的提高产水水质能够维持用水标准。一般出水水质能达到18兆欧以上,以及对TOC 、SIO2都有一定的控制能力。抛光树脂一般用于半导体行业比较多,所谓的抛光就是指树脂的表面处理情况。另外,抛光树脂出厂的离子形态都是H、OH型。

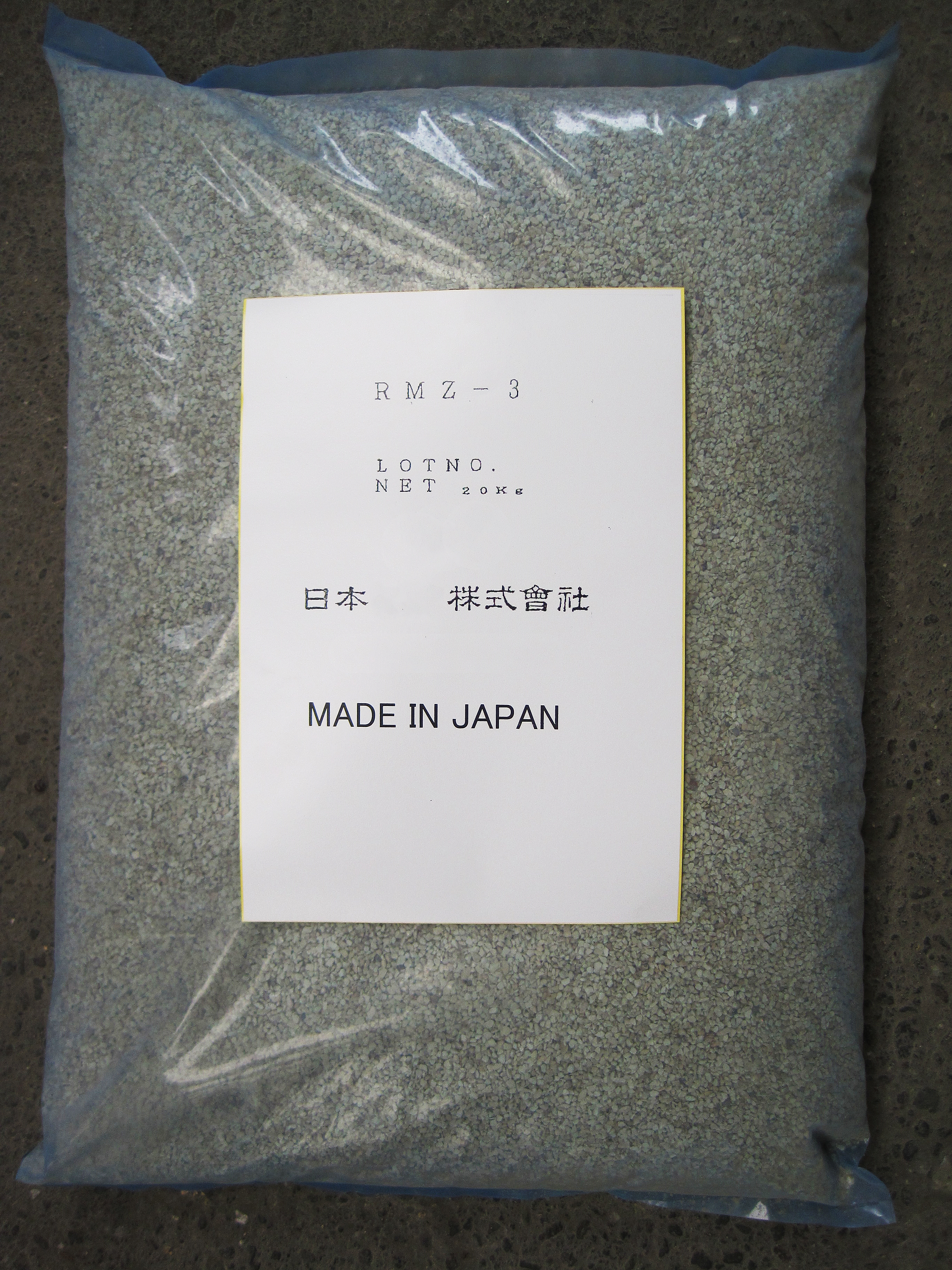

为了在医药、电子或其他行业用电导率0.055μs/cm (电阻率18.2MΩ.CM) 的纯水,在混床或EDI净水设备后,装置抛光混床进行精处理。这种抛光树脂是由密度很接近的阴树脂和阳树脂混合而成的,因无法将种树脂的阴、阳树脂分离,也不能用酸碱将它们分别再生,所以这种抛光树脂失效后,必须丢弃。

精混床抛光树脂装填时的注意事项:

精混床抛光树脂是由氢型强酸性阳离子交换树脂和氢氧型强碱性阴离子交换树脂混合而成的。

1. 首先,如需用装填树脂,请务必将手洗干净,切勿将油脂带入树脂槽内;

2. 如更换树脂,必须完全的清洗桶槽及集水器,不得有老旧树脂残留槽底,否则这些使用过的树脂将会污染水质;

3. 如在作业中,需加入水以方便装填,请务必使用纯水,水份不得太多,同时必须在树脂进入树脂槽后立即将水抽出或排掉,避免树脂的分层;

4.同时每次换装时必须检查相关的零组件,如果有破损现象,必须立即更换掉,检查集水器,如有堵塞,应立马清除;

5.如先填装抛光树脂,那么在插入集水管时将会遇到困难。如一定要必须先装填树脂再插入集水管,则可将已装潢树脂的FRP槽横置于地上,缓慢的滚动槽以松动抛光树脂,再慢慢的将集水管插入树脂中;

6. 树脂装填完并接上管线后,应先将桶槽上端的通气孔打开,缓慢的通入水,直到勇气也溢水且不再有气泡产生后,将通气孔紧闭,开始采水。

今天小编带大家了解一下我们常说的精混床抛光树脂及装填时的注意事项。一般抛光混床用于超纯水处理系统末端,又称之为一次性混床,用来保证或更好的提高产水水质能够维持用水标准。一般出水水质能达到18兆欧以上,以及对TOC 、SIO2都有一定的控制能力。抛光树脂一般用于半导体行业比较多,所谓的抛光就是指树脂的表面处理情况。另外,抛光树脂出厂的离子形态都是H、OH型。

为了在医药、电子或其他行业用电导率0.055μs/cm (电阻率18.2MΩ.CM) 的纯水,在混床或EDI净水设备后,装置抛光混床进行精处理。这种抛光树脂是由密度很接近的阴树脂和阳树脂混合而成的,因无法将种树脂的阴、阳树脂分离,也不能用酸碱将它们分别再生,所以这种抛光树脂失效后,必须丢弃。

精混床抛光树脂装填时的注意事项:

精混床抛光树脂是由氢型强酸性阳离子交换树脂和氢氧型强碱性阴离子交换树脂混合而成的。

1. 首先,如需用装填树脂,请务必将手洗干净,切勿将油脂带入树脂槽内;

2. 如更换树脂,必须完全的清洗桶槽及集水器,不得有老旧树脂残留槽底,否则这些使用过的树脂将会污染水质;

3. 如在作业中,需加入水以方便装填,请务必使用纯水,水份不得太多,同时必须在树脂进入树脂槽后立即将水抽出或排掉,避免树脂的分层;

4.同时每次换装时必须检查相关的零组件,如果有破损现象,必须立即更换掉,检查集水器,如有堵塞,应立马清除;

5.如先填装抛光树脂,那么在插入集水管时将会遇到困难。如一定要必须先装填树脂再插入集水管,则可将已装潢树脂的FRP槽横置于地上,缓慢的滚动槽以松动抛光树脂,再慢慢的将集水管插入树脂中;

6. 树脂装填完并接上管线后,应先将桶槽上端的通气孔打开,缓慢的通入水,直到勇气也溢水且不再有气泡产生后,将通气孔紧闭,开始采水。

What are the mixed resins of Mitsubishi? In fact, Mitsubishi has a relatively fine level of polishing series resins, such as: DIAION KAM115U / DIAION MUPB PLUS / DIAION MUPBT / DIAION SMT50 / DIAION SMT100L / DIAION SMT110L / DIAION SMT110X / DIAION USMT100 / DIAON SMT200L etc ...

Today, the editor will take you through what we often say about the polishing resin of the mixed bed and the precautions when loading. Generally, the polished mixed bed is used at the end of the ultra-pure water treatment system, also known as a disposable mixed bed, used to ensure or better improve the quality of produced water and maintain water standards. Generally, the effluent water quality can reach more than 18 megohms, and it has certain control capabilities for TOC and SIO2. Polishing resin is generally used in the semiconductor industry, so-called polishing refers to the surface treatment of the resin. In addition, the ion forms of polishing resins are all H and OH.

In order to use pure water with a conductivity of 0.055μs / cm (resistivity 18.2MΩ.CM) in the pharmaceutical, electronics or other industries, after the mixed bed or EDI water purification equipment, the device is polished and mixed bed for final finishing treatment. This kind of polishing resin is made by mixing anion resin and cation resin with very close density. Since it is impossible to separate the anion and cation resin of the seed resin, and they cannot be regenerated separately with acid and alkali, after this polishing resin fails, Must be discarded.

Precautions for the loading of polishing resin in the mixed mixed bed:

The precision mixed bed polishing resin is made by mixing hydrogen type strong acid cation exchange resin and hydroxide type strong basic anion exchange resin.

1. First of all, if you need to use filling resin, please wash your hands clean, and do not bring grease into the resin tank;

2. If you change the resin, you must completely clean the tank and the water collector, there must be no old resin remaining at the bottom of the tank, otherwise these used resins will pollute the water quality;

3. If you need to add water to facilitate the filling during the operation, please use pure water, the water content should not be too much, and the water must be pumped out or discharged immediately after the resin enters the resin tank, to avoid resin delamination;

4. At the same time, the related parts and components must be checked each time they are replaced. If there is any damage, they must be replaced immediately. Check the water collector. If there is a blockage, it should be removed immediately;

5. If the polishing resin is filled first, you will encounter difficulties when inserting the water collection tube. If it is necessary to fill the resin first and then insert the water collecting pipe, you can place the FRP groove of the decorated resin horizontally on the ground, slowly roll the groove to loosen the polishing resin, and then slowly insert the water collecting pipe into the resin;

6. Finally, after the resin is filled and the pipeline is connected, the vent hole on the upper end of the tank should be opened first, and the water should be slowly introduced until the courage also overflows and no more bubbles are generated.

同类文章排行

- 日本三菱水处理树脂

- 日本三菱电泳漆树脂有假货吗?

- 日本三菱电泳漆树脂

- 进口日本三菱树脂安全抵达并已进行消杀!通过核酸检测!

- DIAION日本三菱离子交换树脂

- 三菱化学之离子交换树脂

- 日本三菱核质级抛光树脂有哪些型号?

- 日本三菱螯合树脂DIAION CRBT03

- 日本三菱离子交换树脂中国区总代理

- 日本三菱离子交换树脂有什么作用?

资讯文章

- 日本三菱MBR膜组件在电镀废水处理中起到什么作用?

- 日本三菱软化树脂SK1BL

- 日本三菱离子交换树脂怎么再生?

- 日本三菱MBR膜的相关问题?

- 日本三菱脱气膜代理

- 日本三菱离子交换树脂电泳漆阴树脂UBA100X

- 日本三菱离子交换树脂混床阴树脂UBA100MB

- 日本三菱脱气膜中国区域代理

- 日本三菱离子交换树脂在中国有工厂吗?

- 日本三菱离子交换树脂在国内常用的型号有哪些?

- 日本三菱MBR膜有哪些型号呢?

- 日本三菱离子交换树脂中国区总代理

- 日本三菱离子交换树脂USMT200

- 出货原装进日本三菱MBR膜 55E0025SA

- 代理日本三菱MBR膜

- 日本三菱螯合树脂DIAION CRBT03

- 日本三菱混床树脂UBK08和UBA100MB

- 日本三菱离子交换树脂在中国区库存多吗

- 日本三菱离子交换树脂KAM115U

- 日本三菱树脂代理 - 价格调整通知函